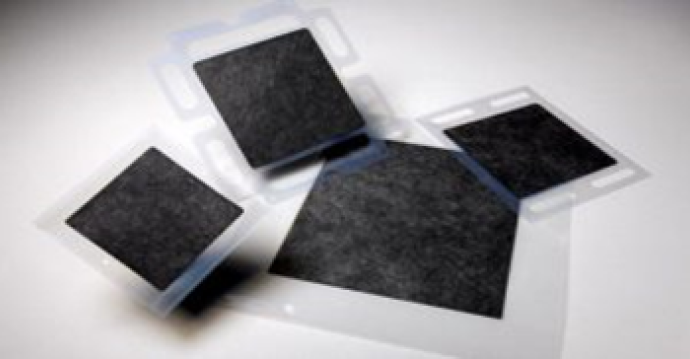

Membrane Electrode Assembly (MEA)

Our Membrane Electrode Assemblies (MEAs) stand at the core of our innovation, driving advancements in fuel cell and electrolyser technology. Designed to meet the needs of both automotive and stationary applications, our MEAs represent a significant advancement in the hydrogen economy.

We leverage strategic partnerships with global companies in the fuel cell and electrolyser sectors incorporating individual stack designs. This allows us to offer tailored solutions that meet any end customer specifications, ensuring that our MEAs integrate seamlessly into diverse systems.

Versatile Layer Configurations of MEAs: 3-5-7

Isondo offers MEAs in 3, 5, or 7-layer configurations, allowing for precise customization to meet the specific requirements of various applications. This flexibility ensures that our MEAs provide optimal performance, longevity, and efficiency.

In this step, gas diffusion layers (GDLs) and other components are added to the CCMs to produce membrane electrode assemblies (MEAs). A 5-layer MEA typically consists of a CCM sandwiched between two GDLs, while a 7-layer MEA includes additional layers for improved gas distribution and water management. These MEAs are essential for efficient electrochemical reactions in fuel cells and electrolyzers.

Nafion-type Membrane & Catalyst Coated Membrane (CCM)

The prepared catalyst inks are coated onto a Nafion membrane, a proton-conductive polymer. This coating forms the catalyst-coated membrane (CCM), which is a critical component of fuel cells and electrolyzers. The coating process must ensure uniform distribution and optimal thickness of the catalyst layer to maximize performance and durability.

Understanding What a Fuel Cell is:

PGM Catalysts

The PGM catalyst is vital to the performance and longevity of the Membrane Electrode Assembly (MEA). Our catalysts are engineered to deliver high efficiency and durability, ensuring optimal performance for both fuel cells and electrolysers.

We are continuously developing novel catalysts through partnerships with local R&D institutions and globally recognized leaders in catalyst development. This collaboration ensures that our products are always at the cutting edge of technology.

PGM Catalyst Types

IPM is installing capability to produce a wide range of precious metal containing catalysts. These could be synthesized specifically for use in automotive catalytic converters, fuel cells, electrolysers, ammonia cracking and other industrial as well as petrochemical applications. This process involves selecting the appropriate PGM (such as platinum, palladium, or rhodium) and creating nanoparticles with high catalytic activity and stability, tailored to the specific application.

MEA/Catalyst Recycling & PGM Recovery

Used catalysts and MEAs as well as production waste are collected for recycling to recover valuable PGMs and the PEM. IPM is developing a process to separate the membranes from the PGM Catalysts and recover both separately. This process involves disassembling the MEAs, separating the components, and using chemical and physical methods to extract the PGMs from the catalyst materials. Recycling helps supplement the demand for PGMs especially with metals like Iridium and also helps minimize environmental impact.

Sustainability & Recycling

Designed with closed loop recycling and cradle to grave responsible business practise at its core, IPM is ensuring that components can be recovered and reused, minimizing environmental impact and contributing to a circular economy in the hydrogen industry. The project will also recycle the spent/waste MEAs and Catalysts back into their constituent PGMs and membrane. Furthermore, as part of our sustainable business practice, IPM s facility has been designed as a zero waste/emission site with dedicated access to solar energy to ensure our electrical inputs are green to the maximum extent.

PGM Refining

The recovered PGMs are then refined to produce high-purity PGM chemicals. These refined PGMs can be used again for catalyst synthesis or sold for other industrial applications. The refining process ensures that the recovered metals meet the stringent quality standards required for high-performance catalytic applications.

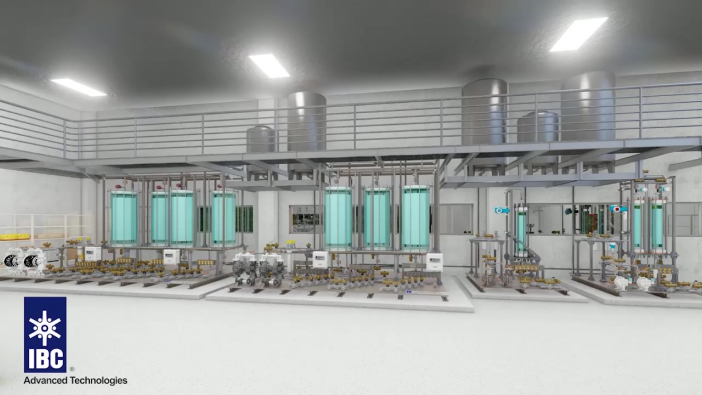

Analytical Services

PM has setup a fully equipped, State of-the Art Analytical & MEA testing Laboratories complying to ISO; LMS 17025, OHAS 45000, EMS 14000 & QMS 9001 standards to provide for the company’s needs in analysing PGM content, PGM Catalysts, Catalyst Precursors & MEA performance. Our laboratories are also able to service customer needs in the following areas :

- Analysis of Precious Metals & related products

- Assays relating to Catalyst Coated Membranes including particle size analysis

- Metal Accounting Assays

- Umpire & 3rd Party Assays

- Sampling & Sample preparation

- Internal Auditing for stock take and compliance

- Preparation of customised laboratory calibration standards: Solid materials & Solutions

- MEA Lifecycle & durability testing

Consulting & Business Development

IPM and recognised experts in all aspects of the PGM and hydrogen industries that are available to assist in developing projects across the spectrum.